Category

ProductsFlame Lamination

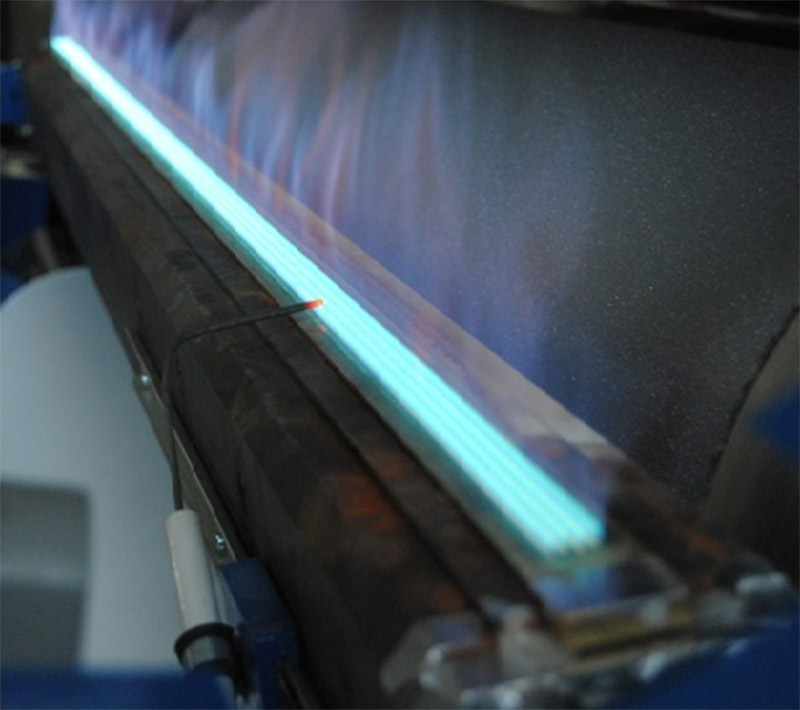

Main activity of our company for 35 years now is the coating of fabrics and synthetic leather with foam using the flame technique (flame lamination). By this technique the fabric or the synthetic leather is coated together with PUR foam (or sometime with scrim depending on the customer’s needs) creating a new product which, however, maintains the characteristics of the initial materials (e.g. elasticity).

The end products of this process can be used in:

- the production of car seat covers, car upholstery (sides/panels of door )headliners and leather foam supports

- production of shoes and slippers

- clothing and underwear production (bras, swimsuits)

- producing of carnival costumes and traditional outfits

- medical equipment

- soundproofing and isolation material

- furniture production, sofa

By laminating foam with fabrics and all kinds of imported plastics, we create our own collections, but we can also provide lamination services of foam with any of our customer’s fabrics (polyester, cotton, many types of synthetic leather). We can laminate materials with foam starting from 1mm to 20 mm thickness and up to 200 cm wide.